Compact pulsed eddy current flaw detector

Pulsed eddy current flaw detector

The compact PE1437 Pulsed Eddy Current Flaw Detector detects metal corrosion under insulation. The device operates even if dirt, rust, paint and scale deposits of total thickness up to 100 mm are on the surface!

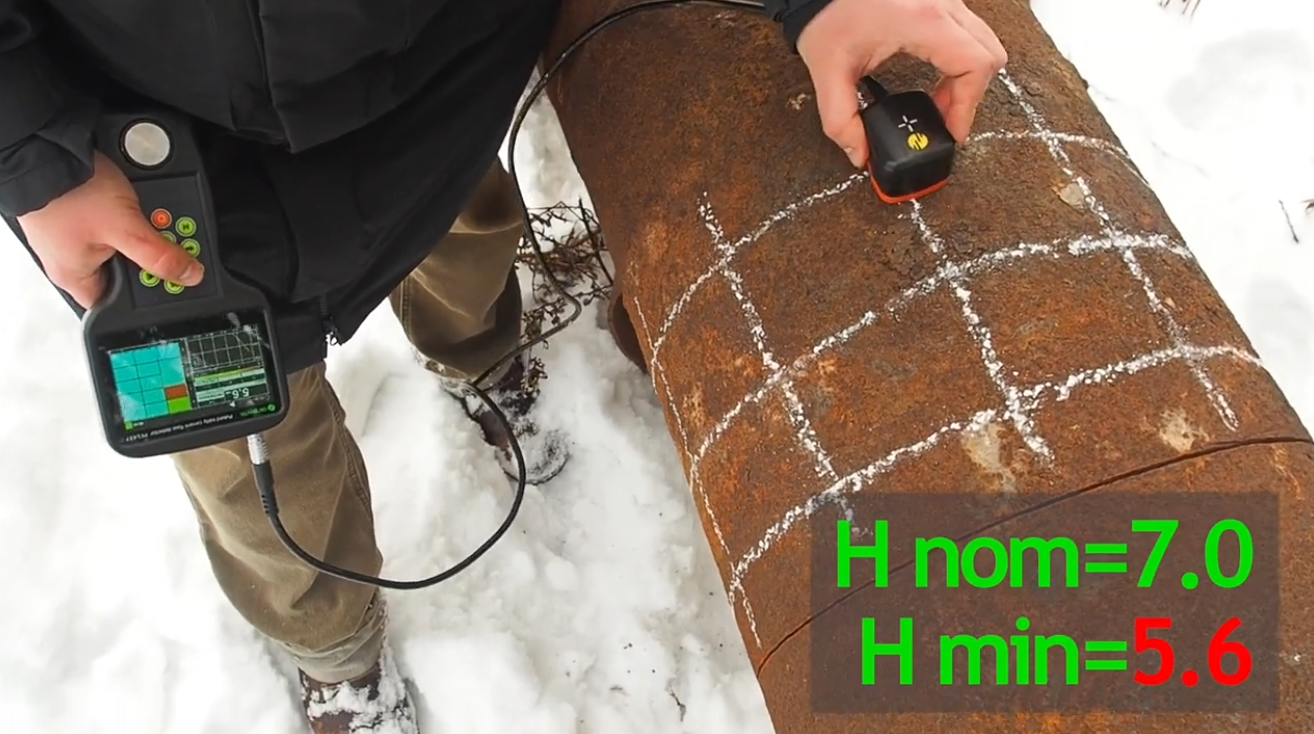

The PE1437 measured the averaged metal thickness under the probe. It is suitable for searching for general area corrosion located both on the external and internal surface of metal. The device implements an algorithm that corrects the measured data when insulation thickness changes, such as when the insulation sags; this change makes a minor effect on the device’s readings.

• Corrosion detection in steel ship parts through a thick layer of paint

• Corrosion detection in metal supports of street lights

• Corrosion detection in pipes and pipelines in polyurethane foam insulation

• Inspection of pipes with internal cement coating from the inside of the pipe

• Corrosion areas detection in pipes through rust without stripping

• Corrosion detection in 3-Layer Polypropylene Coated pipes and pipelines

The probe has IP68 housing and can be used underwater

Bright display shows measured thickness, A-scan and C-scan

...located both on the external and internal surface of metal!

The device comes in a shockproof case, the package includes the device with a protective case, the probe, a charger and a manual.

The PE1437 features:

• The device has the minimum size of a probe, so it can operate on small objects and detect small defects.

The minimal defect is a flat-bottomed bore 20 mm in diameter to a depth of 20% of the nominal thickness;

• The device has a bright display which shows measured thickness, A-scan and C-scan;

• The display is protected by shock-resistant glass;

• The probe has IP68 housing and can be used underwater.

Technical specifications

The PE1437 PEC Flaw Detector

-

Range of measured thickness for steel (with PEC143702)0…12 mm

-

Range of measured thickness for steel (with PEC143703)0…18 mm

-

Average thickness measurement error10%

-

Range of insulation coating thickness (with PEC143702)0…30 mm

-

Range of insulation coating thickness (with PEC143703)0…100 mm

-

Lowest diameter of tested pipes25 mm

-

Temperature of metal in the test object-20…+100°С

-

Temperature of insulation jacket surface in the area of probe placement-20…+60°С

-

Range of operating ambient temperature-20…+50°C

-

Duration of continuous work without battery recharge8 hours

-

Cable length1.5 m

-

Dimensions232 x 135 x 44 mm

-

Weight0.8 kg

ACCESSORIES