Internal pipe

inspection system

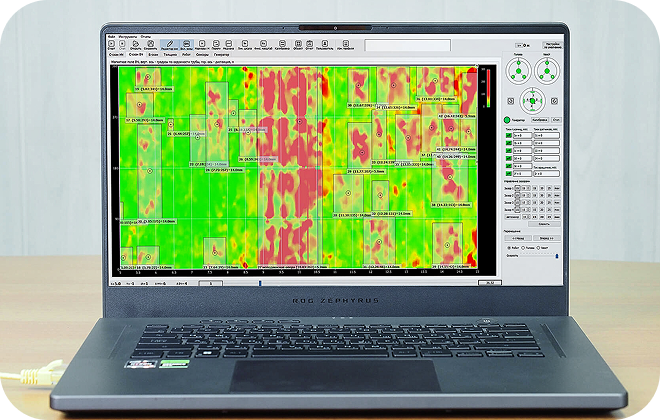

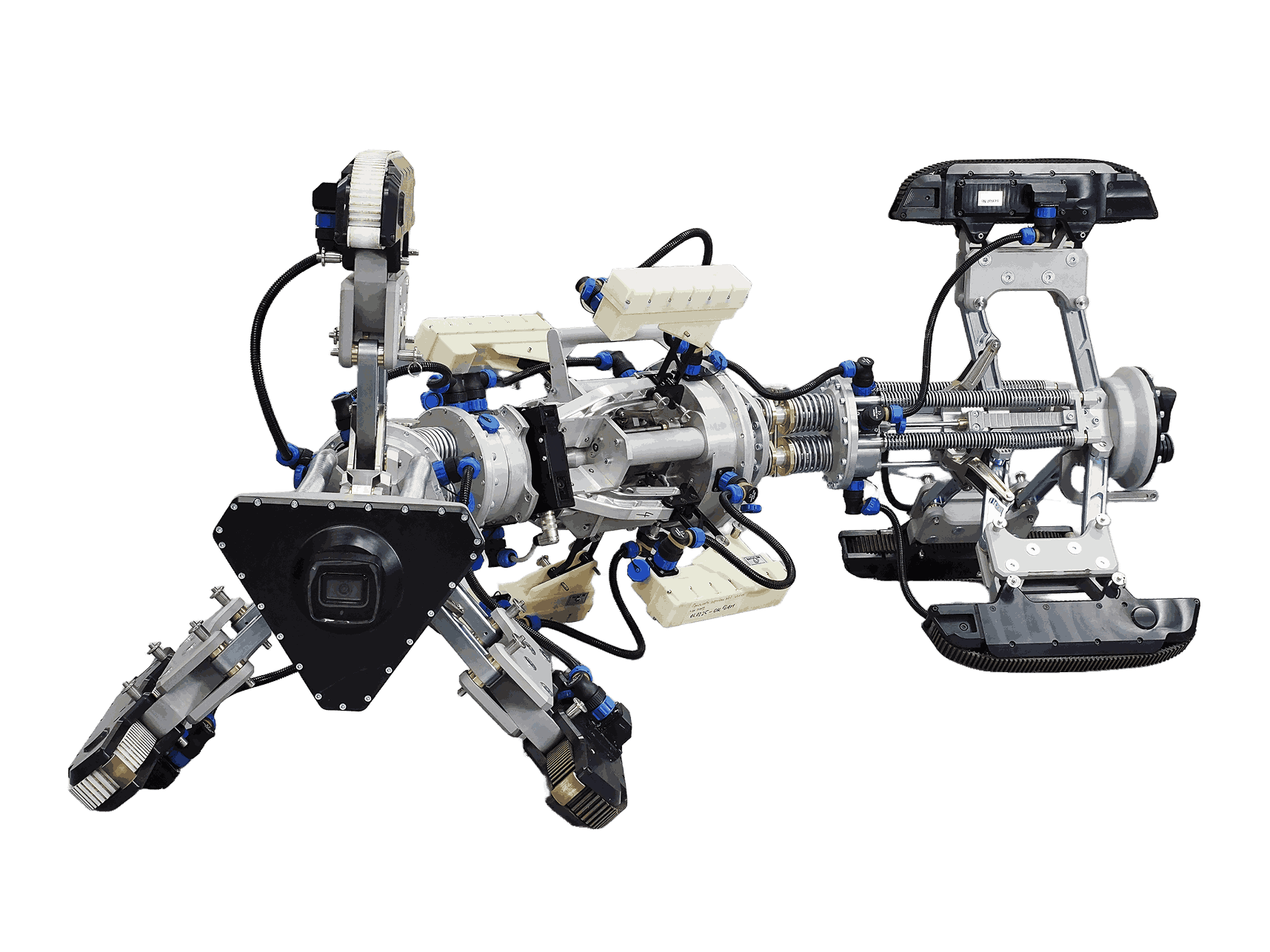

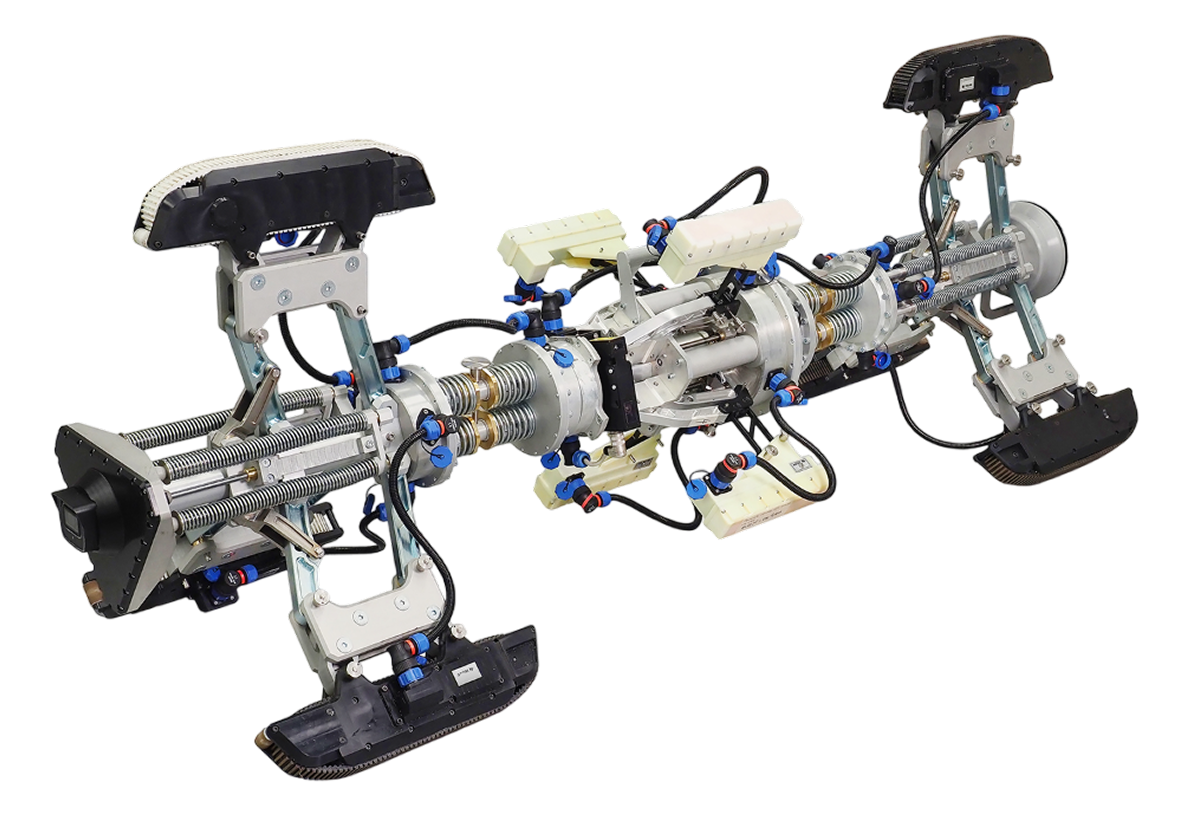

The HeatScan system is designed to detect pipe defects by a diagnostic robot and evaluation of remaining service life of defective areas.

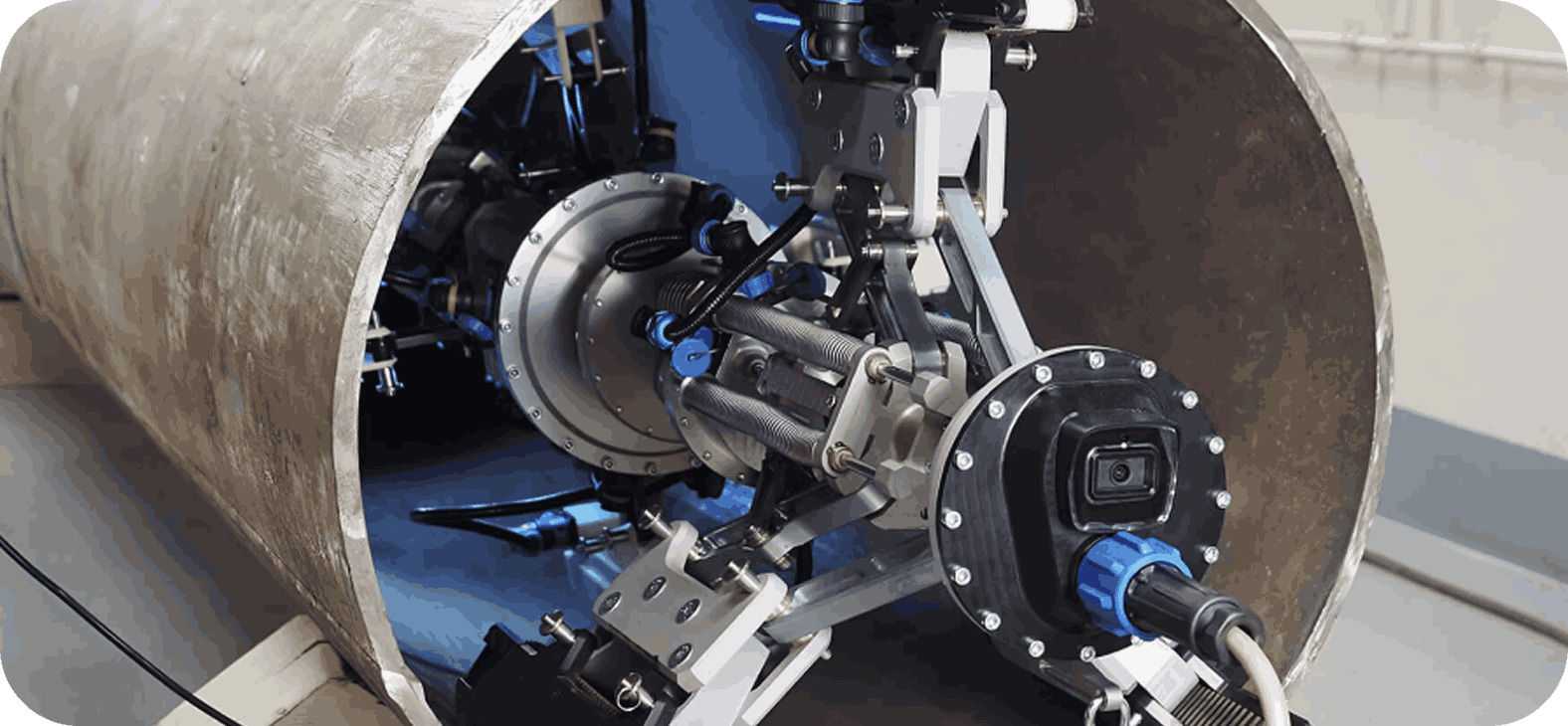

The HeatScan diagnostic system uses a modified magnetic inspection method to detect defects.

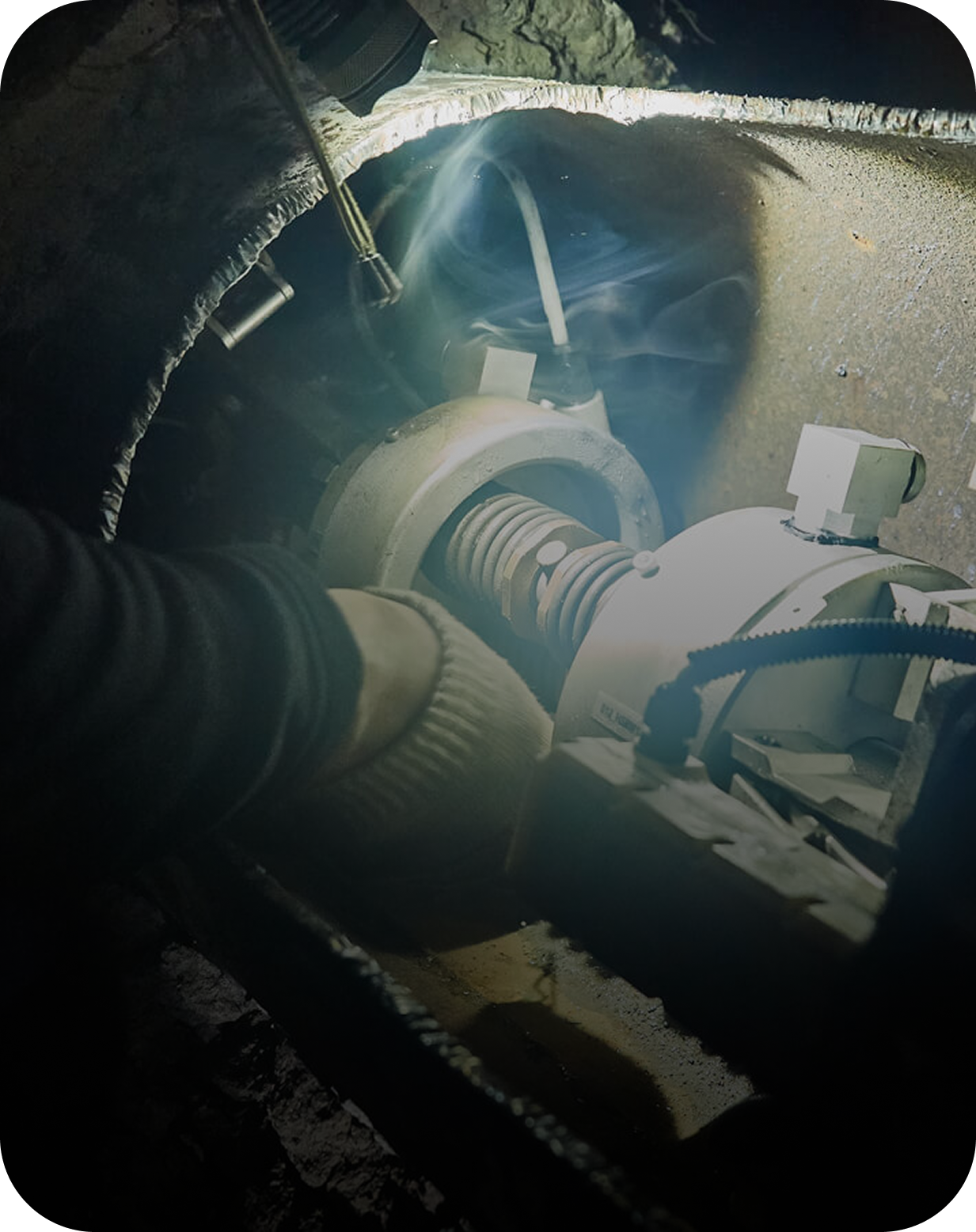

In contrast to the ultrasonic test method, this method is insensitive to pipe surface irregularities caused by corrosion. The robot measures the residual thickness of the metal pipe wall in areas inaccessible for other inspection methods due to deposits and severe corrosion.

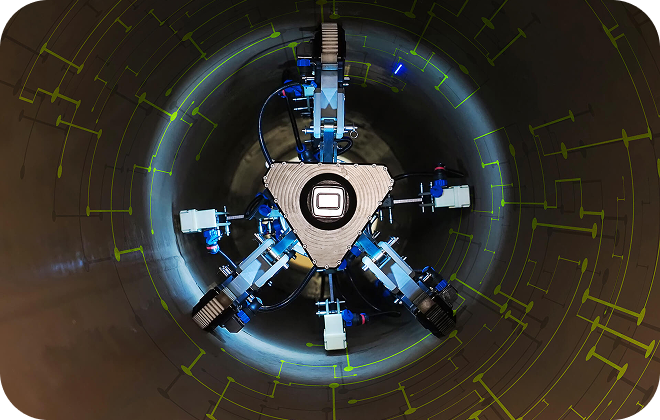

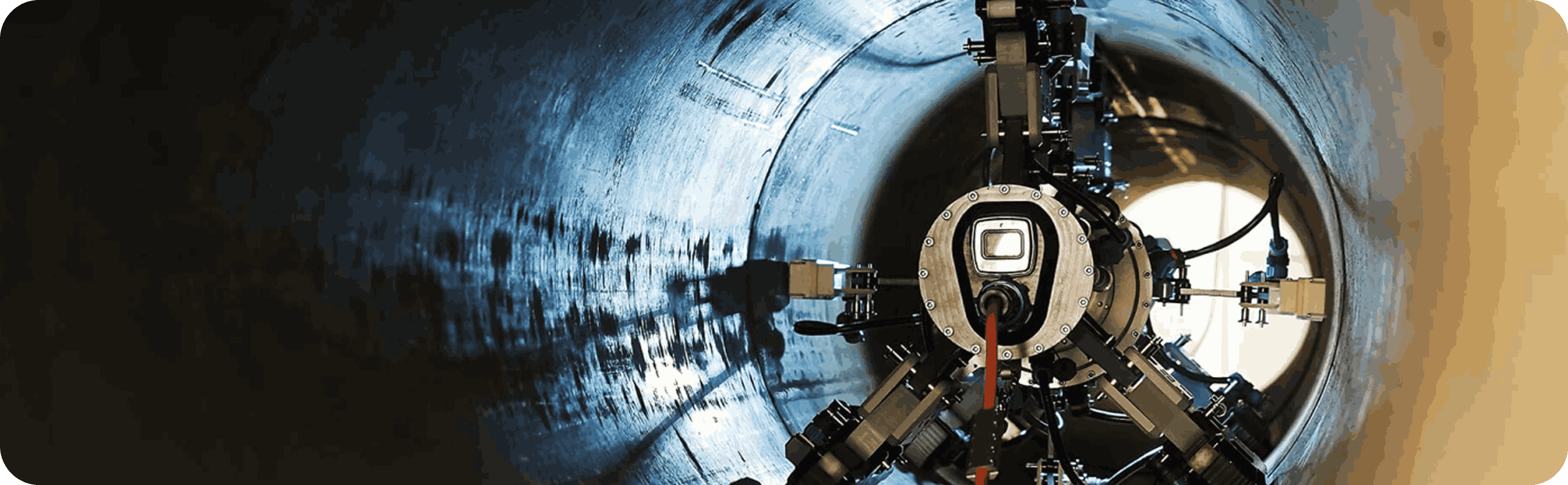

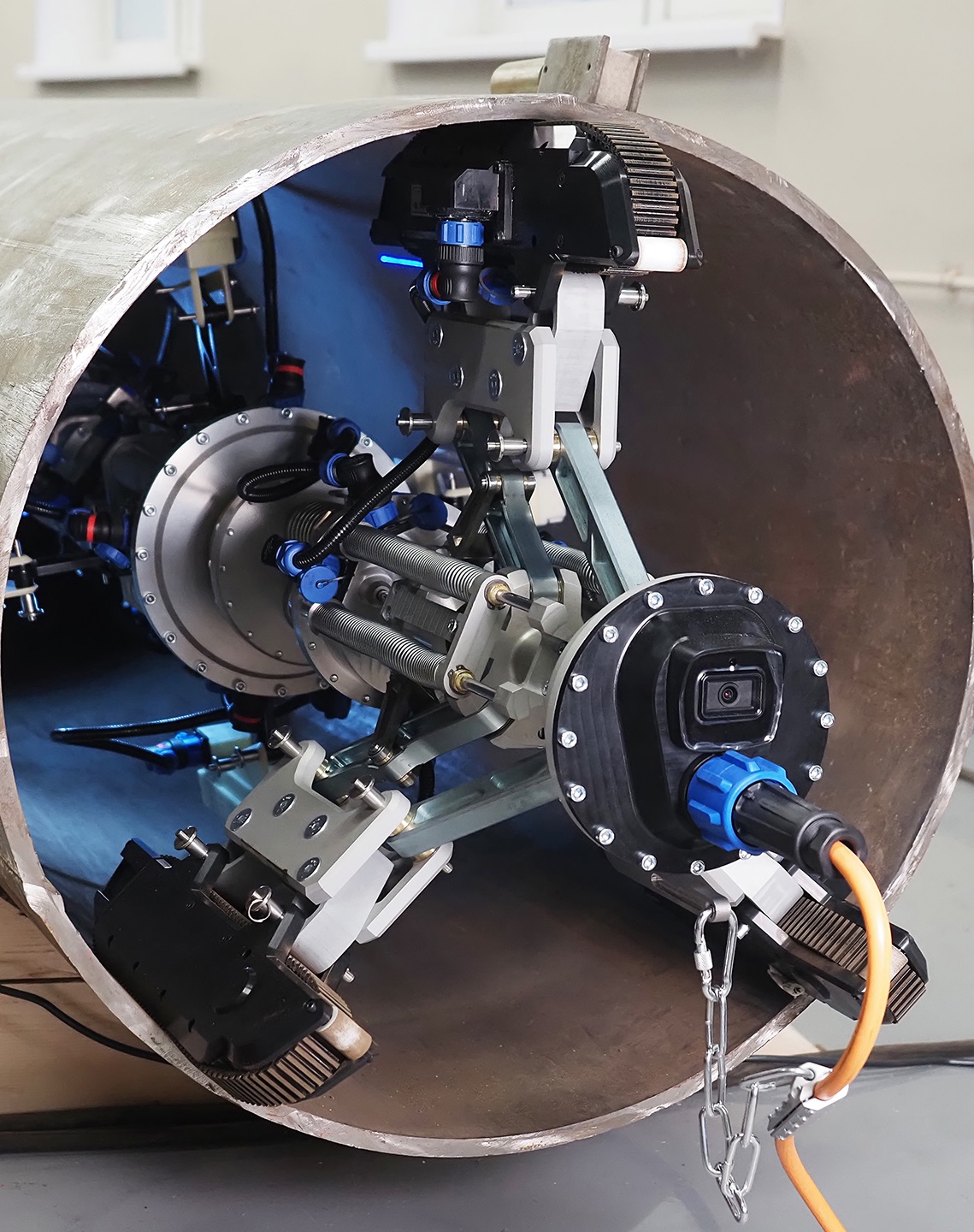

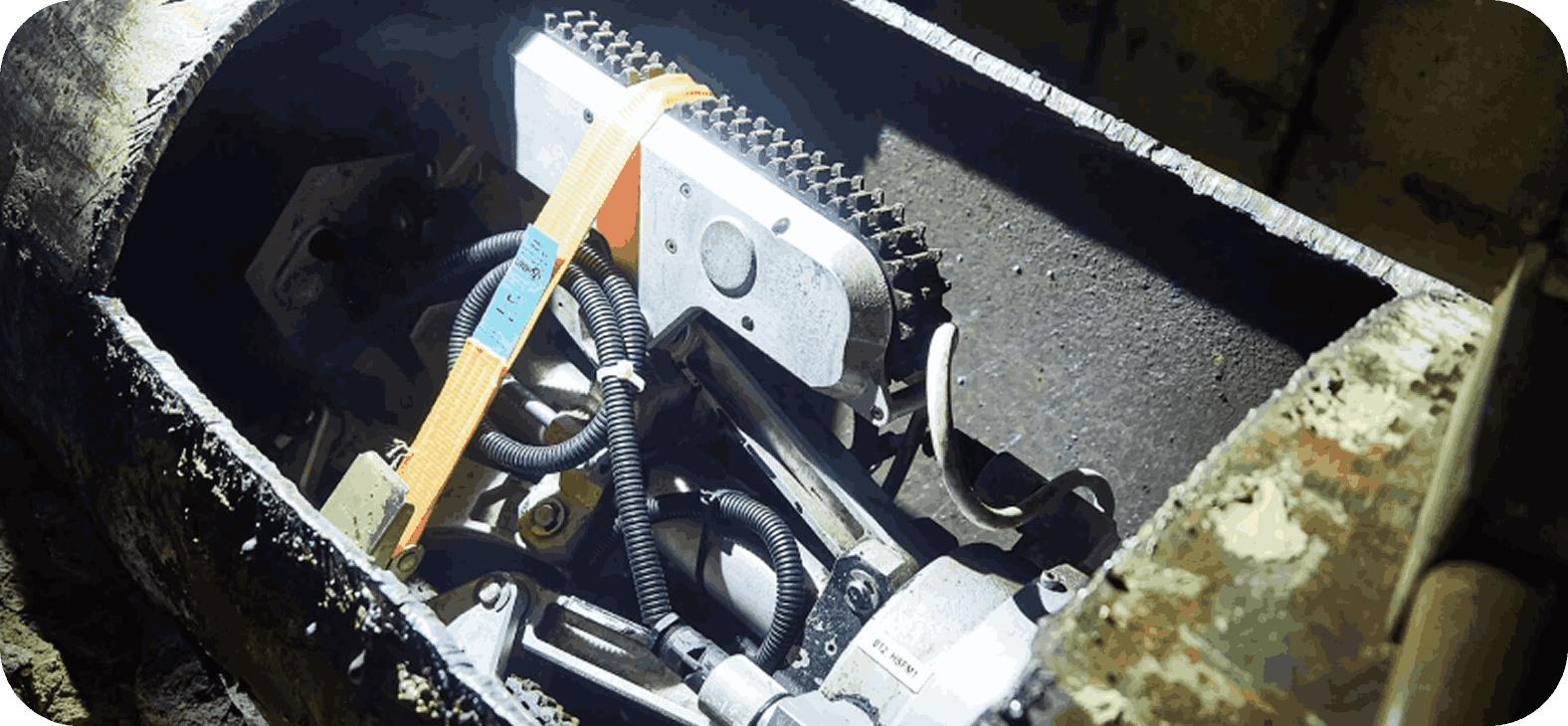

The robot is loaded into the pipe through a cut with minimal dimensions 400 x 600 mm; loading chambers welded into the pipe are not required. No pressurized water in the pipe is required to move the robot and perform the inspection. The robot is controlled by an operator in an auto laboratory placed at the robot loading point.

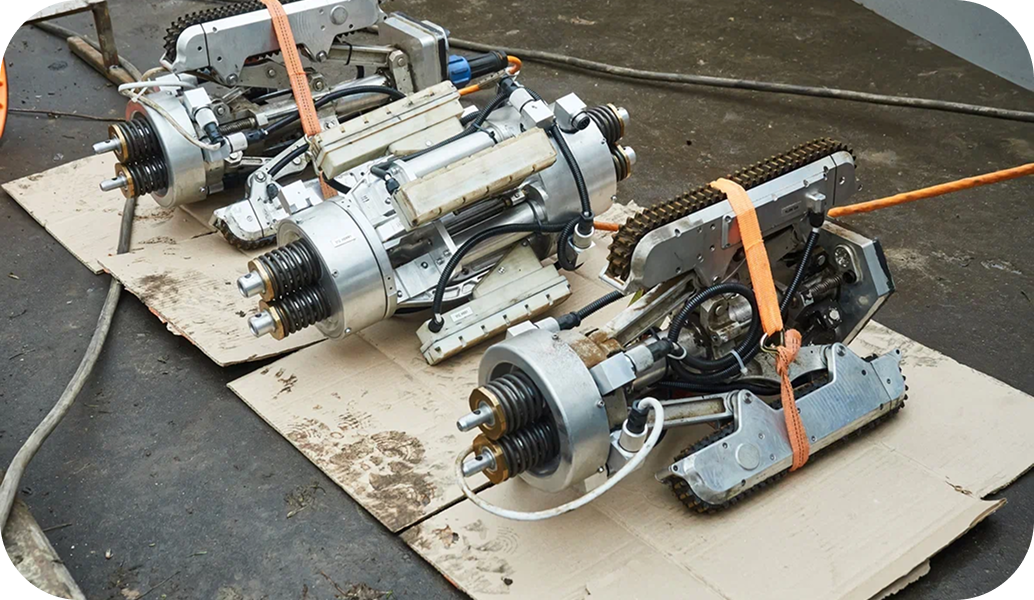

The diagnostic robot has six tracks and can navigate through heavily contaminated areas, allowing metal inspection through deposits up to 35 mm thick.

Our company provides internal pipe inspection services using the HeatScan system.

Modified magnetic test method which requires no preliminary preparation of the pipe.

Testing performance up to 120 m/hour. Requires only 1 operator to perform the inspection

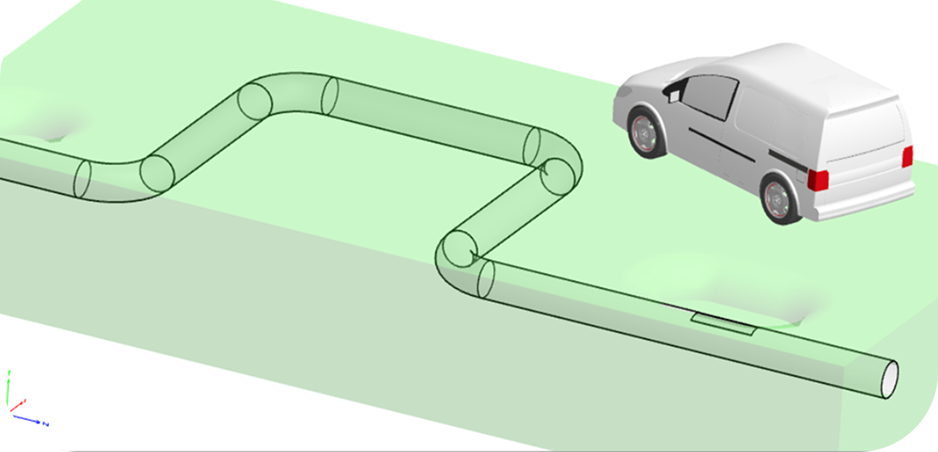

The robot passes through tees and bends in the pipeline.

Technical specifications

-

Pipeline diameterDN400…DN1400

-

Pipe wall thickness1.5…16 mm

-

Pipe length available for inspection in one direction from the loading pointup to 300 m

-

Thickness of deposits on the internal pipe surfaceUp to 35 mm

-

Sizes of detected/measured defectsPenetration defect, diameter 6 mm Сorrosion damage, diameter 30 mm and depth 20% of the wall thickness

-

Performance120 m/h

-

Number of passable bends4 pcs

-

Tee passingYes

-

Measurement error with remaining thickness in the defect zone15% of the remaining thickness

TEST TECHNOLOGY

Easy installation of Heatscan allows you to get results quickly